Blog - Battery Monitoring

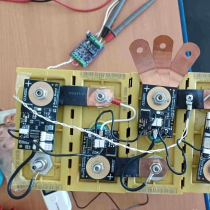

GWLG/Team is testing — thermal release from the terminals

The copper bars server as heat conductors. The purpose of the test is to see how the cell will increase the temperature when there is a source of heat applied.

This also serves to test the function of the BMS, to detect and react to the terminal overheating.

BMS 123 is used for these tests.

&nb

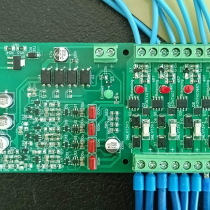

BMS Easy Balancing Board

GWL Team is working on a design ofthe balancing boardthat will be used for 4 cells and will allow balancing up to 10 Amp.

Check the photos from the testing of the first prototype.

More details to follow, when the product will be verified and made available.

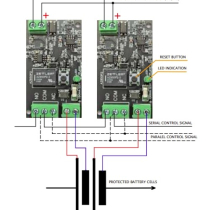

BMS Easy – an easy way to monitor your cells

The BMS Easy is a single cell protection board for the low voltage and over voltage monitoring of the LFP cells.

It allowsthe serial connection of multiple cellsto get a closed circuit with monitoring of larger packs.

It also providesthe parallel connection signal that can be used to rep

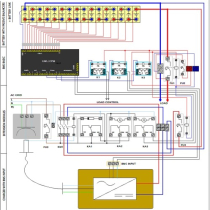

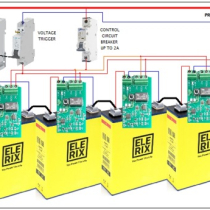

BMS Basic integrated with Charger

Check the connection diagram for the integration of the BMS Basic and the DC Charger

More about (based on the)

Check the quality.

A New Year’s Greeting with a Thermal Runaway

Have you ever burnt the dish on the stove?GWL Team has just begun the New Year with a similar experiencecaused by an improper cell operation.

As a result of a human operator failure and as a result of an improper setting of the charging machine,GWL team has just experience a thermal runaway for a 10

An X-mas Gift

A photo of the Alpha prototype batch for the BMS Easy.

The GWL colleagues are HEROs who keep working at any day and at any time.

Enjoy your X-mas.

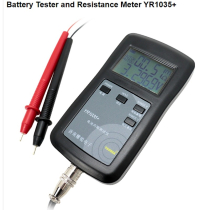

Battery Tester and Resistance Meter YR1035+

The YR1035+ measures the voltage and the internal resistance (Ri)of the cells and batteries. It is one of the most practical and reliable products on the market.

If you need to check the voltage and the internal resistance (Ri) of your cells or batteries, this meter is a must for you.&n

It’s Easy! BMS Easy

Check some more initial connectiondiagrams for the BMS Easy.

BMS Easy is a simple and easy monitoring for individual cells and battery packs.

Stay in touch. More to follow.

In the mean time you can check the.

New project from the GWL’s kitchen: BMS Easy

GWL team has been working on a project of a simple BMS solution. The name isBMS Easy.

More details to be coming in next weeks….

Tips for useful accessories for 12V packs

Check the overview of the useful accessories to make it easier for you to use and.

Ready to go?

English

English Česká republika

Česká republika Germany

Germany France

France España

España Italia

Italia Sverige

Sverige Polski

Polski Nederland

Nederland