Blog - Chargers and charging

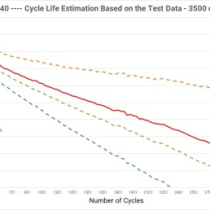

FAQ: What is the Cycle Life Estimation of the Elerix Cells

As given in the datasheet the cycle lifer is specified by the charging and discharging speed, the depth of discharge and the operational temperature.

The typical life span is given at this:

Cycle Life at 80% DOD —- 3000 cycles —- @0.3C/1C, @25°C, >80% SOH

This means that fo

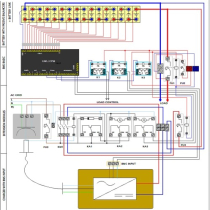

BMS Basic integrated with Charger

Check the connection diagram for the integration of the BMS Basic and the DC Charger

More about (based on the)

Check the quality.

What is the real self-discharge of the LFP cells?

Question: I have received a shipment of LFP cells from you company. When I received them, the voltage was about 3.25V for each cell. Now the voltage is below 3.10 for some cells and some have even just 3.0V or even less. Why is this so?

It is important to realize that cells shipped from GWL have on

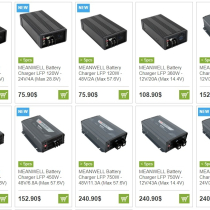

MEANWELL PB Series of Chargers 12V, 24V, 48V

Check the time-limited offer for the MEANWELL PB Series Chargers for 12V, 24V and 48V applications.

.

See also here -

MEANWELL — RS Series — 10W and 15W Power supplies

Great Price/Performance ratio - small size3.3V and 15V power suppliesthat can be usedto charge single cells (LFP 3.65V) and batteries (LFP 14.6V). These power supplies have the user adjustable voltage level.

Note: These products are designed as power supplies. They can be

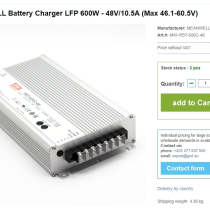

MEANWELL — NPB 120W, 360W, 450W, 750W and 1700W Chargers

The complete product listing of the robust and adjustable chargers from MEANWELL.

The HIGH POWER and yet COMPACT 12V, 24V and 48V chargers.

Follow here for more details: .

MEANWELL HEP 600W Fanless Chargers

Do you need a charger without the noise of the fan (ventilator)? Check the passively cooled MEANWLL HEP series.

Follow here for more details:.

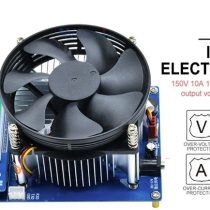

FAQ: Testing the capacity of the cell or battery

Q: I wish to check the capacity of the cell in my battery pack. How to do that?

Answer:Originally there were not any suitable products in the market that would allow the quick and easy testing of individual cells or the packs in a battery. There were only some costly and professiona

A Massive Single Cell Charging – 720 Amps

The photo shows 6 units of theto be used as single cell chargers. The nominal voltage of the power supply isset to 3.6Vand it can charge withup to 120 Amp.

The charging power of the 6 units in parallel will reach3.6V, 720Amps. Is it

MEANWELL – the Charging Solution for 12V, 24V, 48V and...

The universal chargers from MEANWELLto charge the battery packs. See the various product lines:

models for 12V, 24V and 48V.

with passive cooling.

, currents 15A to 120A.

MEANWELL = Quality

English

English Česká republika

Česká republika Germany

Germany France

France España

España Italia

Italia Sverige

Sverige Polski

Polski Nederland

Nederland