GENERAL MANUAL FOR STORAGE, INSTALLATION AND OPERATION

- Eye protection: Use suitable goggles to protect your eyes from chemical substances

- Skin protection: Use protective equipment for your body as well as safety gloves. Prevent physical contact of the chemical substances released from a damaged battery with your skin.

- Preventing inhalation: During overcharge, a short-circuit or mechanical damage, the toxic hydrogen fluoride (HF) gas may be formed and released from the lithium cell. If LFP cells are used in an enclosed space in the presence of persons, it is necessary to ensure adequate protection of the cells and these persons in case of an emergency and HF release.

- If a white gas is released due to overcharge, a short circuit or mechanical damage of the cell/battery, it is necessary to protect all persons present and prevent them from inhaling this gas.

- If possible, relocate the cell outside. If this is not possible, evacuate all persons from the interior area where the gas could spread.

- This gas may contain highly toxic hydrogen fluoride (HF), which if inhaled, can cause death or temporary or permanent health problems.

- charged at 30 - 50% nominal capacity

- in a position with the safety valve and the terminals facing up

- in packaging compliant with the ADR regulation category 9 and marked as „UN 3480“

- Out of reach of children, separate from food, medicine and easily flammable materials

- water vapours, mist and spraying water

- condensation, freezing and temperatures above 40°C,

- vibrations, impact, puncture and the effects of pressure

- direct sunlight and pulsating heat

- aggressive gases and steam

- incorrect positioning

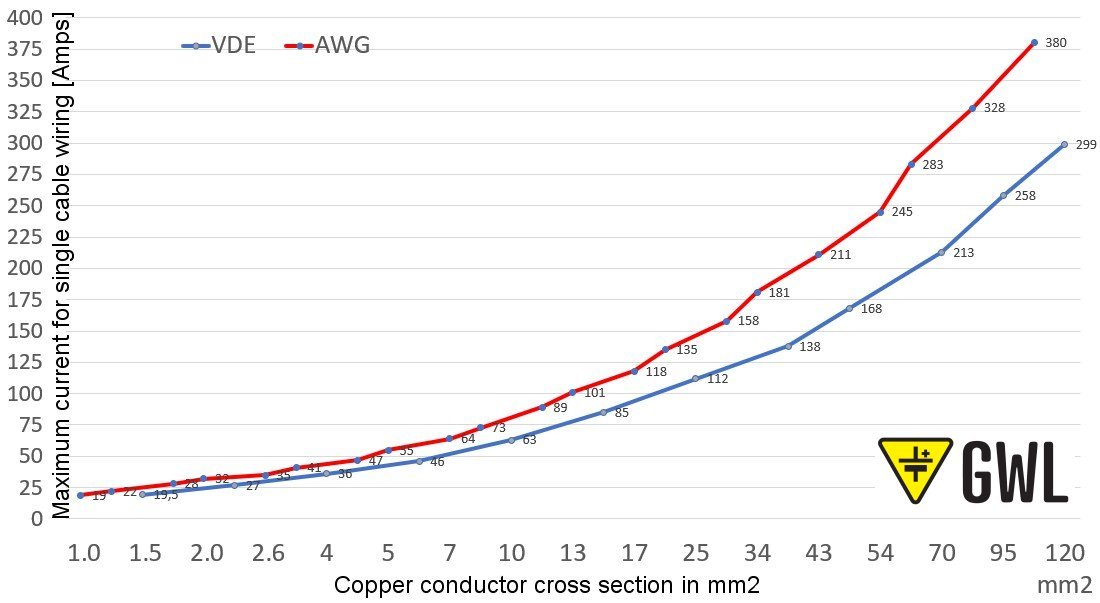

- 4A/1mm2 - permanent

- 6A/1mm2 - short term up to 1h

- 8A/1mm2 - peak max 1 min

- The method of battery collection or recycling:

for this purpose, the manufacturer publishes the current list of battery collection and recycling sites including the location name and address and makes this information available to the end consumer: The collection and recycling site is the Seller‘s seat at the time the Contract was executed, i.e. GWL a.s., Průmyslová 11, Prague 10. - The potential negative effects of materials used in the batteries and accumulators on the environment and human health:

Batteries and cells contain chemical substances that have a negative effect on the environment and human health. Overcharge, short-circuit or mechanical damage may cause the formation and release of toxic hydrogen fluoride (HF) from the battery cell. If LFP cells are being used in an enclosed space in the presence of persons, it is necessary to provide adequate protection to these persons in case of an accident and the release of HF. - The graphic symbol for recycling and collection

and on the purpose of the labels:

This is a graphic symbol for separate waste collection:

Lithium cells and batteries are sources of electrical voltage and current that can be used over and over again. They may be used to replace other types of accumulators as long as the correct overall voltage and maximum current is maintained. They do, however, have different charging and discharging properties than lead-based accumulators (SLA, VRLA) as well as those based on nickel and cadmium (NiCd, NiMH).

POTENTIAL RISKS

Risk of Short-circuit and Fire

Charged and uncharged cells contain a large volume of electrical energy, which can ignite the connecting wire during a short-circuit causing an electrical spark or an electrical arc. The lithium cells contain organic solvent, which can catch fire, for example from heated contacts, from a spark etc. The plastic housing of the cell may also ignite as can other flammable substances.

Risk of Injury from Direct Current

When connecting a larger number of cells and batteries into a series, the risk of DC current injury increases. Do not touch electrical wires or other components that are energized under any circumstances. In certain instances, even a so-called safe current that is lower than 60V can cause fatal electrical current injury.

Chemical Substance Risk

Lithium cells and batteries do not contain any corrosives or acids. They do, however, contain chemical substances, which affect the human body and which may cause a chemical reaction, e.g. heavy metals and organic solvents. It is therefore necessary to proceed according to the following principles when handling cells and batteries:

END CONSUMER INFORMATION

Only a person who was adequately trained and informed on the use of lithium cells and batteries may use the batteries. The information is provided and the training is carried out by the final seller. For remote sales, instructions are provided in an operating manual, which is included in the delivery. Other information on cell usage is listed on the seller‘s website.

RULES FOR TRANSPORTATION, USAGE AND STORAGE OF LITHIUM CELLS

Lithium cells are transported as dangerous goods according to the ADR regulation and are ineligible for air transportation in most cases. Do not transport them in passenger cars, do not send them in standard packages sent via regular mail or a courier service. You could cause significant property damage as well personal injury.

Cells are stored and transported in the following manner:

It is necessary to protect the cells from unfavorable external conditions, especially:

Batteries may be stored in their original fiberboard non-flammable packaging in stacks of 3 at most. When stacking them in other packaging or in stacks of more than 3, cells may become deformed and there is a risk of fire or the release of chemical substances.

The cell terminals and the plastic housing must not be welded, soldered, opened, repaired or modified mechanically. Otherwise, you risk being exposed to dangerous chemical substances.

Do not close the cells into packaging or covers, which would cover or block the safety valves on the top of the cells. Potential modifications must be first consulted with the Seller and the Seller‘s written statement on the matter should be provided.

Do not mix cells from various manufacturing series, even if they are of the same type and capacity, and do not install such cells together. Always use cells from the same manufacturing series and delivery batch for every battery.

Operate batteries under supervision or using constant monitoring via a protective and control BMS system, see below. Protect from overcharge and undercharge.

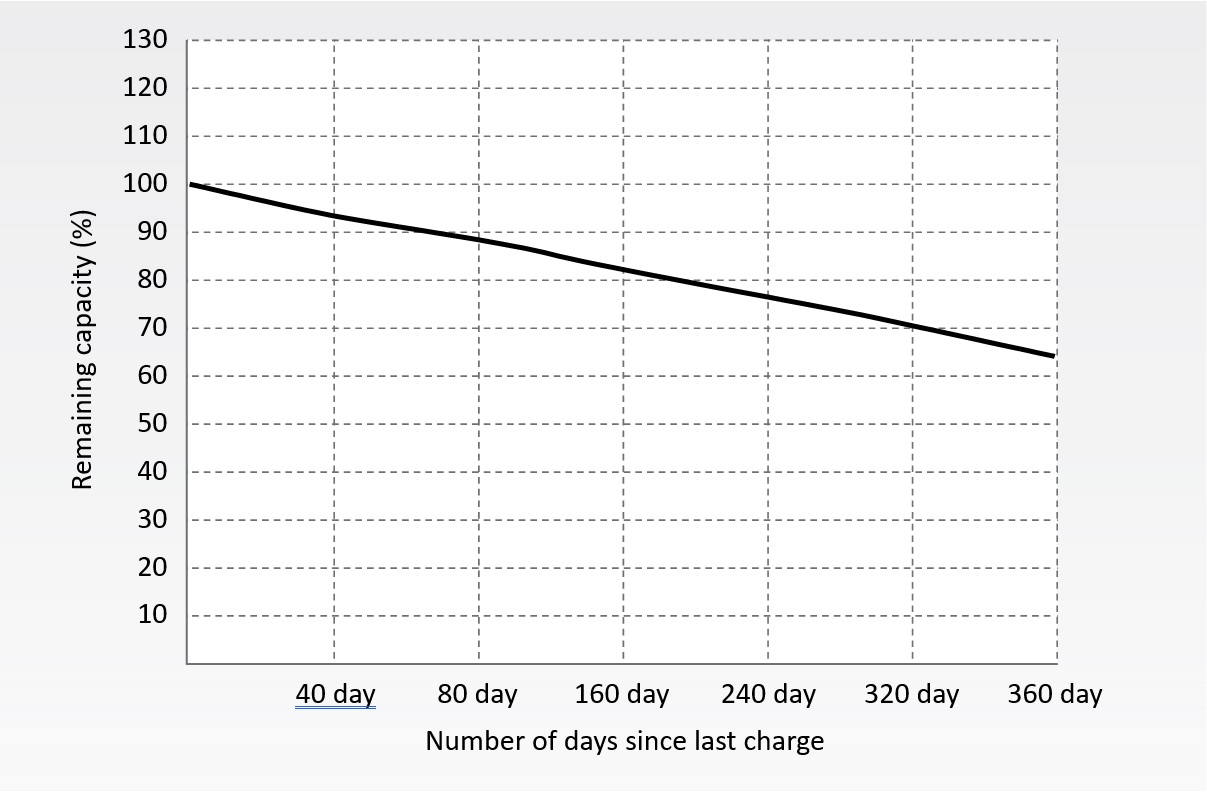

SELF-DISCHARGE

Most LiFePO4 batteries and cells have a very slow rate of self-discharge. It is therefore possible to store them for a long time following the initial charge. The typical course of discharge is listed in the specification of each cell.

INITIAL CHARGE

New LFP/LFYP cells arrive from production partially charged. It is essential to charge the batteries to full capacity prior to first use. This initial charge should be carried out using a current of 0.5C at most with voltage as per the battery or cell specifications (usually 3.8V for LiFePO4). The battery capacity increases gradually during the first few cycles. The cell must not discharge or charge to full capacity using a current of more than 1C (double the capacity) during the first few cycles. It is only possible to use the cells in full scope as per the specifications after 5 cycles.

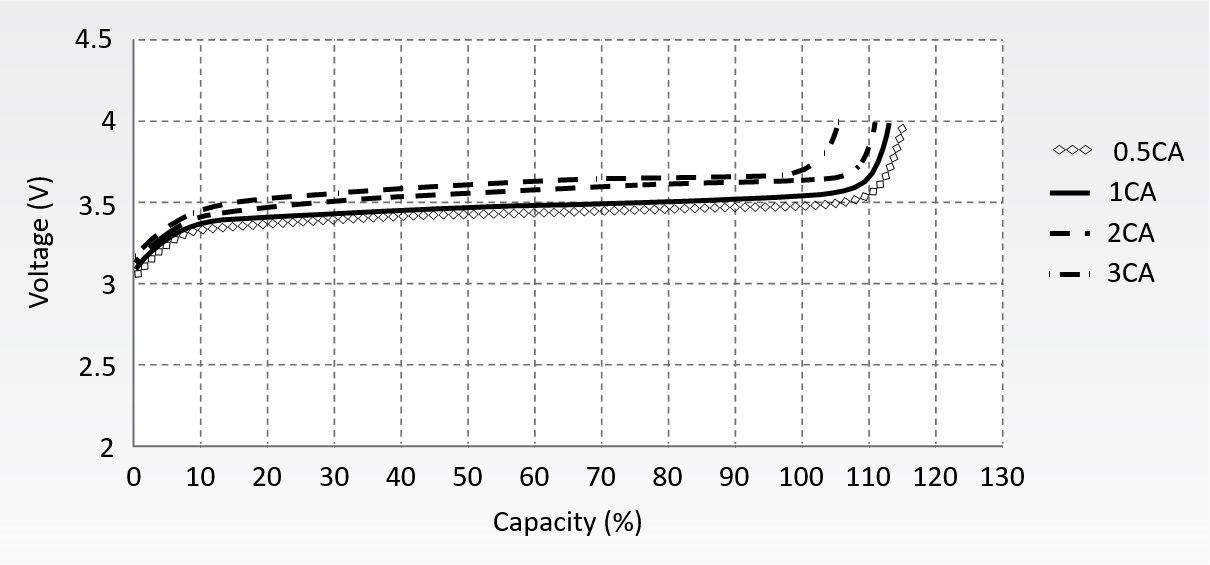

STANDARD CHARGING OF LIFEPO 4 CELLS / BATTERIES

Carefully check the highest charge voltage according to the specification of the cell or battery. If this charge level is exceeded (usually 3.8 to 4.2V / cell) the cell/battery will become irrevocably damaged and the warranty will be lost.

The cells/batteries do not have a memory effect and it is therefore possible to charge and discharge them any time. Repeated short charging/discharging cycles do not affect the life-cycle of the battery. The maximum charge current for individual cells and batteries are listed in the specifications. The cells must not be kept (i.e. charged) using a voltage of more than 3.50V (so-called float or absorption mode). Once the maximum charge voltage is reached (usually 3.60V) it is necessary to stop charging and not continue until the cell or battery is discharged by at least 10% of its nominal capacity. This voltage only applies to standard LiFePO4 cells at standard temperatures, i.e. 15°C – 35°C. Example of VA characteristics during charging using various currents:

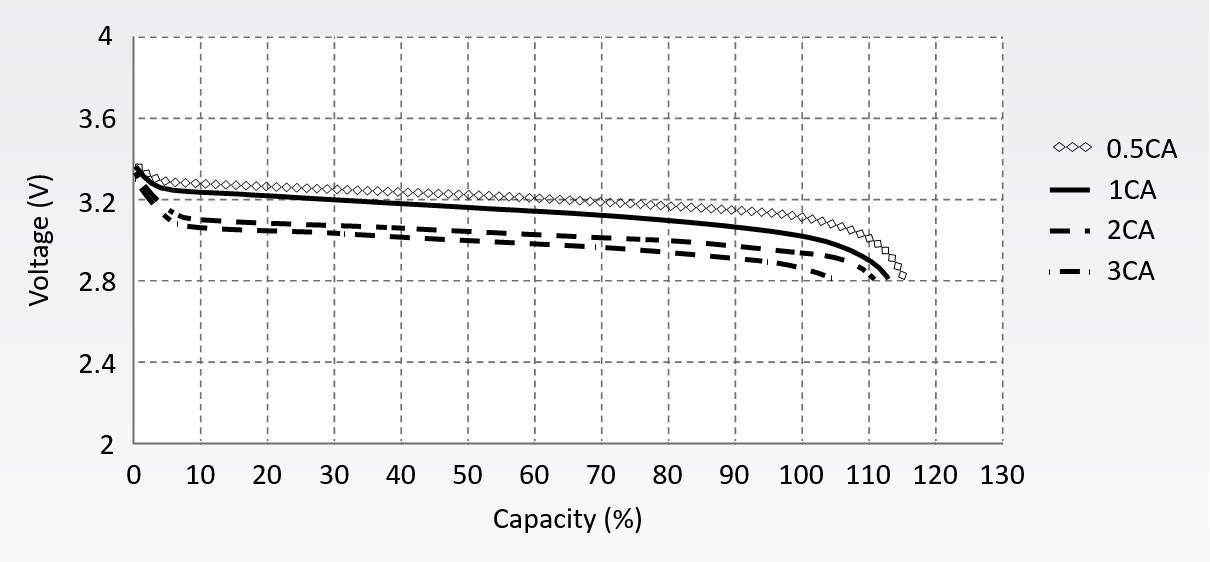

STANDARD DISCHARGE OF LIFEPO4 / CELLS

Carefully check the lowest charging voltage as per the cell or battery specifications. When voltage drops below the lowest range (usually 2.50V for LiFePO4, 25°C), the cells are damaged irreversibly and the warranty is lost. Example of V-A discharge characteristics during various currents:

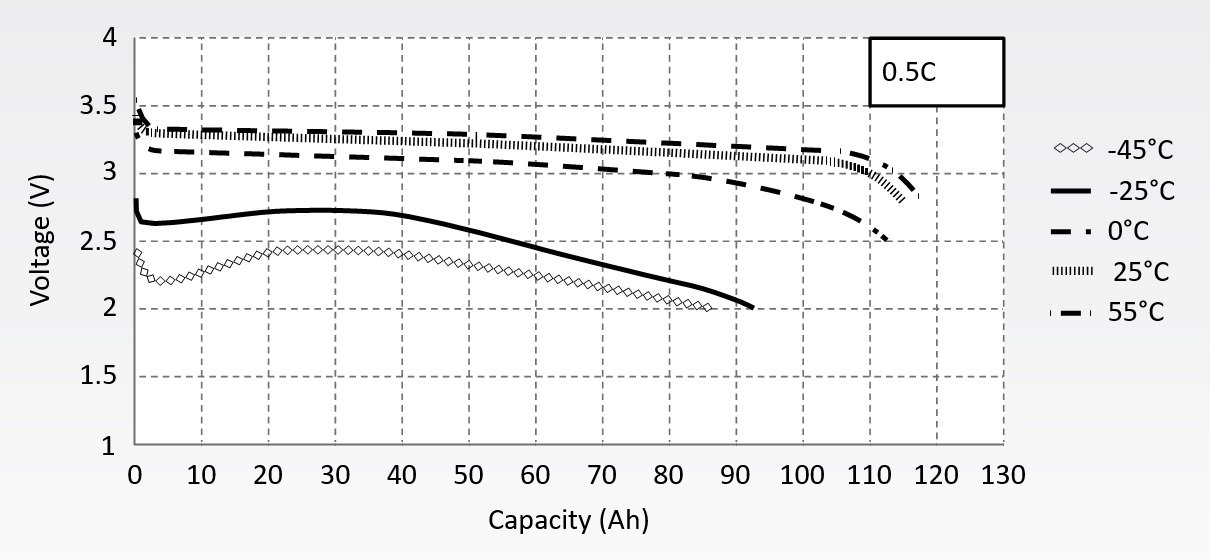

CHARGING LIFEPO4 CELLS / BATTERIES AT NON-STANDARD TEMPERATURES

The LiFePO4 cell electrical properties change at temperatures of under 5°C, especially in terms of marginal voltages, internal resistance and capacity. Please note the technical specifications of each cell model. Generally, one should count on a decrease of the actual voltage of a cell as well as of the limits for their charge and discharge. Example:

For standard cells based on LiFePO4 technology, the temperatures displayed in this graph generally apply. Example: at a temperature of –25°C, it is necessary to change the setting of the protective BMS circuits so that the discharge of the cells will only stop once 2.0V is reached and the cell is fully charged only once 2.8V is reached. The maximum capacity (measured in Ah), which the cell is able to absorb and release will be about 92% of the nominal capacity.

CHECKING ON BATTERY AND CELL STATUS

The cell and battery status and potential balancing of cells and batteries to the same voltage is carried out once cell/batteries in the series are charged, using a physical check at the installation site and further by connecting the charger/protective equipment to every single cell/battery. The cells/batteries status check and potential balancing to the same voltage must be carried out in the following intervals at least:

1) during the initial charge2) after the first cycle

3) after the first 5 cycles or 7 days depending on what comes first

4) after the first 20 cycles or 30 days depending on what comes first

5) continuously once every 200 cycles or 12 months depending on what comes first

The Buyer is obligated to keep written records on the inspections carried out and to archive these records and present them when filing a warranty claim.

CONNECTING THE CELLS AS BATTERY

The cells can be connected in parallel (increases capacity), in serial (increases voltage) or in serial-parallel (increases voltage and capacity). A lot of information is described on our technical blog, please follow the link below and you will get to the information guide on the topic of connecting cells. Use only the original terminal connectors supplied by GWL with the cells.

→ The proper installation of the battery connectors

Terminal connectors from other manufacturers or various replacements (solid straps) can damage the cells due to their lower flexibility.

Do not use other than the supplied stainless steel bolts and nuts. Fasteners made of other materials (galvanized, brass, copper, etc.) can damage the terminals, or you may not be able to loosen and unscrew them over time.

Immediately before installing and tightening the terminal connectors on the terminals, carefully clean the contact surfaces with sandpaper with a grit of approx. 200. Oxidation of the terminals, or their blackening from the fitted rubber cover, is a natural phenomenon that is not related to the date of manufacture, does not change the properties of the cell and does not affect its lifetime.

Tighten the bolts carefully and firmly. For ALUMINUM cells with small terminals (ELERIX Brand) the force is up to 4 N/m. For WINSTON cells with large terminals the maximal force is: 9 N/m for 40 and 60 Ah cells, 20 N/m for 90-200 Ah cells and 60 N/m for 300 AH cells and larger. Check the proper tightening regularly.

How to calculate the maximum current for a given terminal connector?

The important parameters for the calculation are the cross-section of the terminal connector multiply by the width of the terminal connector.

See recommended current load per 1mm2

The load capacity of the terminal connector is not linear! The load capacity decreases with increasing cross-section of the terminal connector.

You can also read more at our blog

USE OF THE BMS SYSTEM

When the Buyer connects the lithium cells into a battery series, the Buyer is obligated to also install an electronic system for monitoring and recording individual statuses (electrical voltage, temperatures etc.) of every cell, also called „BMS.“

To ensure proper function and for the purposes of any potential warranty claims, it is necessary to continuously monitor the cells and the batteries. In the event of a defect or incorrect function of a cell occurs, it is necessary to put this cell/battery out of operation. In order for the warranty to apply, it is necessary to legitimately prove (e.g. using records from BMS) that the cell or batteries were not discharged below the minimum voltage level or that they were not overcharged above the maximum voltage level using records from BMS or another monitoring device.

WARNING:

WARNING:

Most BMS systems have their own at-rest consumption, which may discharge the cell below the lowest permitted voltage. If you are using such a system (e.g. BMS123), it is essential that you periodically charge the cells.

WARNING:

WARNING:

Do not rely on a single method of protection from overcharge or discharge. Always install two independent forms of protection.

EXPECTED LIFESPAN OF LIFEPO4 CELLS/BATTERIES

No. of months from the purchase date or the no. of charge cycles, depending | Expected actual capacity of the cell as compared to the nominal capacity for discharge and charge with current of 0,5 C at most within 10 - 90 % of the nominal capacity |

|---|---|

up to 6 months / < 500 cycles | >95 % |

6 - 60 months / < 2000 cycles | >80 % |

60 - 120 months / < 3000 cycles | >60 % |

This table is an example only. The specific remaining cell capacity depends on many factors such as temperature of the environment, operational currents, BMS used etc.

RECYCLING BATTERIES AND CELLS - INFORMATION REQUIRED BY LAW REGARDING THE FOLLOWING:

Do not throw batteries into municipal solid waste or into a fire, do not burn them or throw them out at landfill sites. Dispose of batteries at a battery recycling center or a battery collection site.

English

English Česká republika

Česká republika Germany

Germany France

France España

España Italia

Italia Sverige

Sverige Polski

Polski Nederland

Nederland